About Paper

Paper is a thin material and is produced by pressing together moist fibers, typically cellulose pulp derived from wood, rags or grasses, and drying them into flexible sheets. It is used for writing upon, printing upon or for packaging.

Paper can be produced with a wide variety of properties, depending upon its intended use:

Chemical Pulping

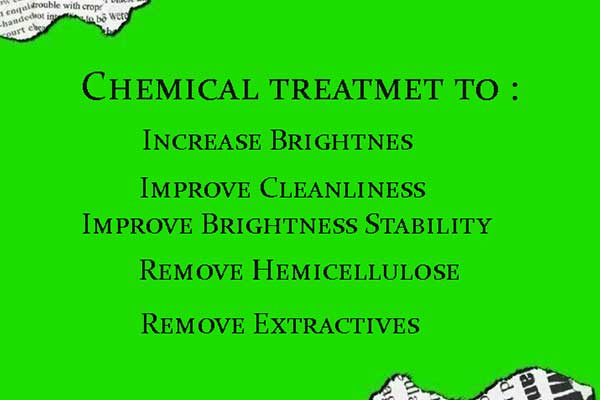

The purpose of a chemical pulping process is to break down the chemical structure of lignin and render it soluble in the cooking liquor, so that it may be washed from the cellulose fibers. Because lignin holds the plant cells together, chemical pulping frees the fibres and makes pulp. The pulp can also be bleached to produce white paper for printing , painting and writing . Chemical pulps tend to cost more than mechanical pulps , largely due to the low yield, 40-50% of the original wood. Since the process preserves fibre length, however, chemical pulps tend to make stronger paper. Another advantage of chemical pulping is that the majority of the heat and electricity needed to run the process is produced by burning the lignin removed during pulping.

Paper made from chemical pulps are also known as wood-free papers . Not to be confused with tree-free paper.

The Kraft process is the most commonly practiced strategy for pulp manufacturing and produces especially strong, unbleached papers that can be used directly for bags and boxes but are often processed further, e.g. to make corrugated cardboard.

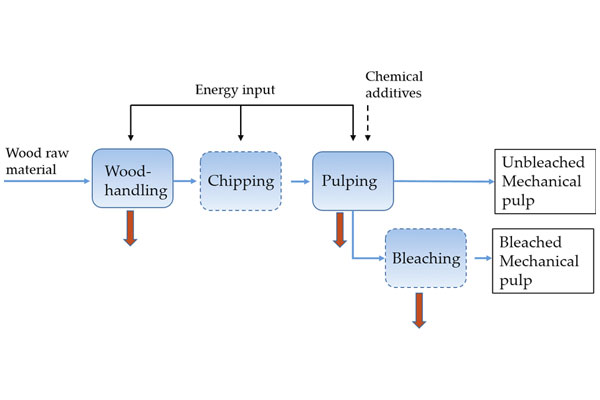

Mechanical Pulping

There are two major mechanical pulps, thermo mechanical pulp (TMP) and groundwood pulp (GW). In the TMP process, wood is chipped and then fed into large steam-heated refiners where the chips are squeezed and fibreized between two steel discs. In the groundwood process, debarked logs are fed into grinders where they are pressed against rotating stones and fibreized. Mechanical pulping does not remove the lignin, so the yield is very high, >95%, but also causes paper made from this pulp to yellow and become brittle over time. Mechanical pulps have rather short fibre lengths and produce weak paper. Although large amounts of electrical energy are required to produce mechanical pulp, it costs less than chemical pulp.

Deinked Pulp

Paper recycling processes can use either chemical or mechanical pulp. By mixing with water and applying mechanical action the hydrogen bonds in the paper can be broken and fibres separated again. Most recycled paper contains a proportion of virgin fibre in the interests of quality. Generally deinked pulp is of the same quality or lower than the collected paper it was made from.

There are three main classifications of recycled fibre :

- Mill Broke or Internal Mill Waste: this incorporates any substandard or grade-change paper made within the paper mill which then goes back into the manufacturing system to be repulped back into paper. Such out-of-specification paper is not sold and is therefore often not classified as genuine reclaimed recycled fibre. However, most paper mills have been recycling their own waste fibre for many years, long before recycling become popular.

- Preconsumer Waste: this is offcuts and processing waste, such as guillotine trims and envelope blank waste. This waste is generated outside the paper mill and could potentially go to landfill, and is a genuine recycled fibre source. Also includes de-inked preconsumer (recycled material that has been printed but did not reach its intended end use, such as waste from printers and unsold publications).

- Postconsumer waste: this is fibre from paper which has been used for its intended end use and would include office waste, magazine papers and newspaper. As the vast majority of this paper has been printed (either digitally or by more conventional means such as litho or gravure), it will either be recycled as printed paper or go through a deinking process first.

Recycled papers can be made from 100% recycled materials or blended with virgin pulp. They are (generally) not as strong or as bright as papers made from virgin pulp.

Additives

Besides the fibres, pulps may contain fillers such as chalk or china clay, which improve the characteristics of the paper for printing or writing. Additives for sizing purposes may be mixed into the pulp and/or applied to the paper web later in the manufacturing process. The purpose of sizing is to establish the correct level of surface absorbency to suit the ink or paint.

Producing Paper

The pulp is feed to a paper machine where it is formed as a paper web and the water is removed from it by pressing and drying.

Pressing the sheet removes the water by force. Once the water is forced from the sheet, felt (not to be confused with the traditional felt ) is used to collect the water. When making paper by hand, a blotter sheet is used.

Drying involves using air and or heat to remove water from the paper sheet. In the earliest days of papermaking this was done by hanging the paper sheets like laundry. In more modern times, various forms of heated drying mechanisms are used. On the paper machine, the most common is the steam-heated can dryer. These dryers can heat to temperatures above 200°F (93°C) and are used in long sequences of more than 40 cans. The heat produced by these can easily dry the paper to less than 6% moisture.

Finishing

The paper may then undergo sizing to alter its physical properties for use in various applications.

Paper at this point is uncoated. Coated paper has a thin layer of material such as calcium carbonate or china clay applied to one or both sides in order to create a surface more suitable for high-resolution halftone screens. (Uncoated papers are rarely suitable for screens above 150 lpi.) Coated or uncoated papers may have their surfaces polished by calendering. Coated papers are divided into matte, semi-matte or silk, and gloss. Gloss papers give the highest optical density in the printed image.

The paper is then fed onto reels if it is to be used on web printing presses, or cut into sheets for other printing processes or other purposes. The fibres in the paper basically run in the machine direction. Sheets are usually cut "long-grain", i.e. with the grain parallel to the longer dimension of the sheet.

All paper produced by paper machines as the Fourdrinier machine are wove paper, i.e. the wire mesh that transports the web leaves a pattern that has the same density along the paper grain and across the grain. Textured finishes, watermarks and wire patterns imitating hand-made laid paper can be created by the use of appropriate rollers in the later stages of the machine.

Wove paper does not exhibit "laidlines", which are small regular lines left behind on paper when it was handmade in a mould made from rows of metal wires or bamboo. Laidlines are very close together. They run perpendicular to the "chainlines", which are further apart. Handmade paper similarly exhibits "deckle edges", or rough and feathery borders.

Applications Paper

To write or print on: the piece of paper becomes a document ; this may be for keeping a record (or in the case of printing from a computer or copying from another paper: an additional record) and for communication.

Paper can be produced with a wide variety of properties, depending on its intended use.

Our Fundamental Values

To represent a value

paper money, bank note, cheque, security voucher and ticket.

For storing information

book, notebook, magazine, newspaper, art, zine, letter and personal use like diary, notes, scratch paper. Paper can also be used for written communication.

For packaging

corrugated box, paper bag, envelope, wrapping tissue, Charta emporetica (see glossary) and wallpaper.

For cleaning

toilet paper, handkerchiefs, paper towels, facial tissue and cat litter.

For construction

Papier-mache, origami, paper planes, quilling, Paper honeycomb (see glossary), used as a core material in composite materials , paper engineering , construction paper (see glossary) and clothing (see glossary).

Other uses

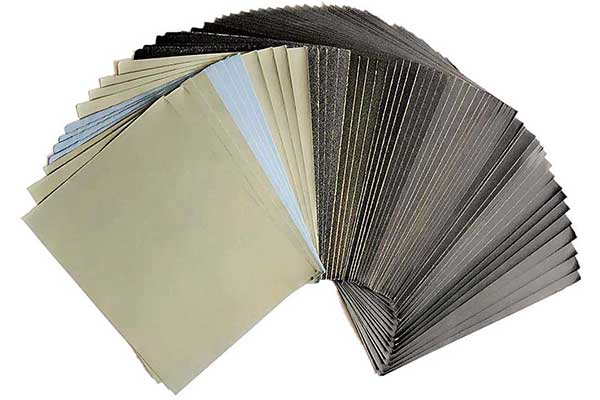

Emery paper, sandpaper, blotting paper, litmus paper, universal indicator paper, paper chromatography, electrical insulation paper and filter paper.

To know more about paper please visit Paper History and Glossary.